GMP auditing serves as the cornerstone of pharmaceutical quality assurance and product safety. As we approach 2025, we’re seeing a growing emphasis on comprehensive audit processes that provide a big-picture look at organizational compliance with Good Manufacturing Practice regulations. These audits typically take for simple assessments and up to ten days for complex manufacturing sites. between one to three days

What is a GMP audit exactly? At its core, a GMP compliance audit ensures products are manufactured and controlled according to appropriate quality standards and current industry best practices. The GMP audit procedure typically begins with careful planning to identify scope and objectives, followed by execution either by internal staff or qualified contracted auditors. Additionally, the quality systems approach in GMP includes the coordination of all of which should be assessed during an audit.

For quality managers, understanding these processes is crucial because GMP compliance directly impacts patient safety and product efficacy. Furthermore, with regulatory bodies like the FDA conducting facility inspections to assess compliance with current Good Manufacturing Practice regulations, staying ahead of requirements is not optional—it’s essential. five subsystems

In this article, we’ll explore everything quality managers need to know about GMP auditing in 2025, from procedure basics to emerging technologies that are transforming how we approach compliance.

Understanding the GMP Audit Procedure from Start to Finish

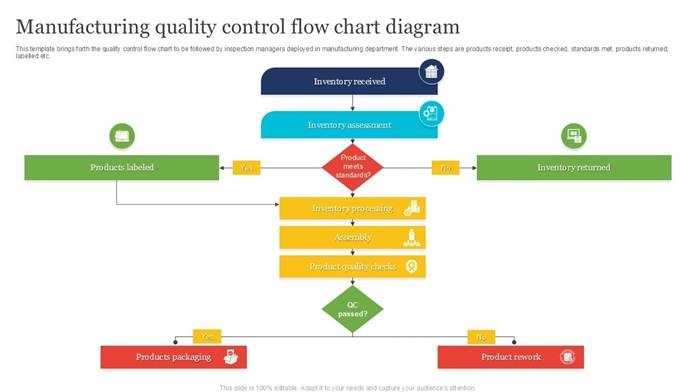

Image Source: SlideTeam

A successful GMP audit follows a structured sequence of activities that unfolds in distinct phases. Rather than a single event, the audit represents a comprehensive process that typically begins weeks before the actual site visit and continues well after the auditors leave the facility.

Audit planning and scope definition

Initially, the process begins with determining who will conduct the audit—either a single auditor or an audit team. For team audits, a lead auditor typically organizes the team, plans the audit activities, communicates with the auditee, prepares the agenda, and coordinates audit reporting. The scope must be limited to manageable parts of the system that can be completed in a reasonable timeframe while allowing for sufficient depth of review.

Prior to conducting a GMP audit, quality managers should give careful consideration to defining the audit boundaries. This involves identifying specific processes to be covered while maintaining flexibility to follow audit trails when needed. A well-structured audit plan includes clear objectives, identification of audit team members, and references to applicable standards the auditee is expected to meet.

The audit schedule should be accessible to authorized team members only, with amendments permitted solely by the Quality Manager or designated delegates. Any changes to subject matter, frequency, or planned audit dates must be properly documented with reasons provided.

Opening meeting and facility walkthrough

The formal audit begins with an opening meeting between auditors and key site personnel. This meeting, typically lasting about 15 minutes, establishes the framework for the evaluation. The lead auditor should introduce the team members, confirm the audit program, arrange a tentative time for the closing meeting, and explain the audit process and reporting method.

Following the opening meeting, auditors conduct firsthand observations of manufacturing operations. This facility walkthrough serves multiple purposes: identifying both deficiencies and good compliance practices, confirming documentation issues, verifying corrective actions from previous findings, and validating information obtained during interviews.

Document review and evidence collection

Document examination constitutes one of the most time-consuming yet critical parts of a GMP audit. Auditors systematically review Standard Operating Procedures (SOPs), comparing them with actual practices and evaluating record-keeping for:

· Completeness and accuracy of entries

· Proper signatures and dates

· Equipment calibration and maintenance logs

· Personnel training records

· Batch records and deviation handling

When collecting evidence, auditors must identify appropriate, reliable sources and specify date ranges aligned with the audit scope. The chain of custody and data security are paramount considerations when gathering either hard copy or digital evidence. All evidence should be logged in a tracking system, evaluated for accuracy and completeness, and properly referenced within working papers.

Closing meeting and audit report delivery

Once the on-site portion concludes, a closing meeting presents audit findings to the auditee’s management. All key participants from the audit should attend this meeting, where auditors summarize observations, classify findings based on severity (critical, major, or minor), and outline next steps.

The closing meeting isn’t meant to be a complete verbal recitation of the report but should focus on the most important findings. Auditors typically present major nonconformities first, followed by minor ones, and then opportunities for improvement, ending on positive observations to change the tone.

Subsequently, the audit team delivers a comprehensive written report documenting all observations, recommendations for corrective actions, and expected implementation timelines. This report serves as the foundation for the facility’s corrective and preventative action (CAPA) plans and may require verification through follow-up audits.

Top GMP Audit Checklist Areas to Monitor in 2025

Effective GMP auditing requires focused attention on key areas that regulatory bodies consistently scrutinize. Quality managers must concentrate their efforts on these critical compliance hotspots that remain fundamental to GMP audit success in 2025.

Personnel training and qualification records

Personnel qualification requirements represent a significant compliance focus, with FDA inspections frequently citing ‘Training, Education, Experience overall’ among the top inspectional observations. Consequently, quality managers should ensure training records demonstrate that:21 CFR 211.25(a)

· Employees receive GMP training continuously, not just during onboarding

· Training occurs immediately after critical procedural changes

· Records clearly indicate the training date, content, and signatures of both employee and trainer

· Documentation proves training effectiveness through competency assessments

· Records remain readily retrievable to determine what training an employee has received

Moreover, training records must match each employee’s specific role rather than relying on generic sign-in sheets. In 2025, regulators expect to see clear documentation showing trainers have appropriate qualifications, particularly for technical topics like validation or aseptic techniques.

Equipment calibration and maintenance logs

Equipment maintenance documentation remains essential for demonstrating GMP compliance. Auditors specifically look for:

· Written procedures establishing cleaning and maintenance protocols for each piece of equipment

· Records of preventive maintenance performed according to established schedules

· Calibration documentation showing each measurement device was checked according to approved written procedures

· Evidence that clean equipment is properly identified with cleaning dates and protected against contamination before use

In pharmaceutical facilities, particularly for non-dedicated equipment, insufficient cleaning validation and maintenance documentation can lead to FDA warning letters citing . Quality managers should specifically verify that equipment logs include signatures of technicians performing maintenance activities along with dates and times.

Batch records and deviation handling

Batch record review constitutes one of the most time-consuming yet critical parts of GMP audits. Thorough batch record examination should verify:

· Records are complete with proper documentation that each manufacturing step was executed

· In-process tests and environmental conditions are properly documented

· Raw materials, components and equipment preparation are accurately recorded

· All calculations are correct and verified

FDA regulations stipulate that batch record entries must be made contemporaneously—as close to the event as possible. Any deviations found during batch record review must be thoroughly documented, investigated, and resolved according to standard procedures. Quality assurance must review and sign each verification step to ensure compliance.

Environmental monitoring and cleaning validation

Environmental monitoring programs have gained increased importance, especially with updated Annex 1 requirements emphasizing contamination control strategies. Effective programs should include:

· Monitoring for both viable and non-viable airborne particles

· Surface contamination monitoring

· Personnel monitoring in aseptic areas

· Clearly defined sampling locations and frequencies based on risk assessment

For cleaning validation, regulators expect more than just residue limits—they demand lifecycle thinking and toxicological justification. The validation process must demonstrate that equipment cleaning procedures effectively remove product residues, with validation protocols addressing worst-case scenarios for drugs with higher toxicities or lower solubility in cleaning solvents.

How to Prepare Your Team and Facility for an Audit

Image Source: GxP Training

Preparing thoroughly for GMP audits minimizes disruptions and maximizes compliance outcomes. Through systematic readiness strategies, quality managers can transform potential stressful events into opportunities to demonstrate operational excellence.

Creating a GMP audit SOP and training staff

First, establish a written GMP audit procedure that serves as your roadmap to consistent audit performance. This procedure should clearly outline , scope definition, and whether audits will be announced or unannounced. In essence, your SOP must document minimum requirements for who conducts audits and how they are performed.audit frequency (at least annual)

Staff training must extend beyond basic GMP principles to include audit-specific readiness. Ensure employees receive:

· Initial training during onboarding

· Immediate retraining after SOP revisions

· Refresher training at scheduled intervals

· Role-specific instruction for audit responses

to demonstrate effectiveness. Furthermore, auditor qualification must be formally established through education, experience, and specialized training in audit techniques.Document all training with signatures, dates, and competency assessments

Setting up a dedicated audit war room

The audit war room functions as your operation’s command center during inspections. This space should be located away from high-traffic areas yet close to the inspection room. Stock your war room with essential documents that auditors typically request, including:

· Organizational charts and facility layouts

· Quality System Manual and site SOPs

· Staff training documentation and qualification records

· Equipment maintenance logs and batch records

Designate a War Room Coordinator familiar with all aspects of your operation to manage document requests efficiently. This individual must maintain an accurate log of all requested items and ensure proper preparation of personnel before they interact with auditors.

Conducting internal audits and mock drills

Internal audits represent one of the most effective preparation tools, ideally scheduled 6-12 months before external inspections. Begin with a gap analysis comparing current practices against regulatory requirements, then prioritize corrective actions based on risk.

Mock inspections should simulate actual audit conditions by:

· Having supervisors act as inspectors asking common questions

· Testing staff knowledge of procedures and document locations

· Walking through material, personnel, and waste flows

· Evaluating gowning procedures and clean/dirty area segregation

Critically, treat mock inspections with the same rigor as actual regulatory audits to build muscle memory for proper responses. Additionally, assign specific roles during drills, including a primary liaison who remains calm under pressure and possesses comprehensive knowledge of your systems.

Leveraging Third-Party GMP Auditing Services

Third-party GMP auditing services offer pharmaceutical companies a strategic alternative to relying solely on internal audit resources. As GMP requirements grow increasingly complex, many organizations find external expertise valuable for maintaining compliance and reducing risk.

When to outsource GMP audits

Several scenarios warrant consideration for outsourcing GMP audits. First, personnel shortages often create resource constraints that make external auditors necessary. Second, geographical challenges arise when suppliers operate in distant locations like China, India, or South America, requiring specialized cultural knowledge. Third, organizations should consider third-party services whenever specialized technical expertise is needed that exceeds internal capabilities.

Pharmaceutical companies typically outsource GMP audits in these specific situations:

· When auditing contract manufacturing organizations or API suppliers

· For routine supplier monitoring where shared audits provide cost advantages

· During periods of high audit demand that exceed internal bandwidth

· When complex regulatory requirements demand specialized auditor expertise

Evaluating auditor qualifications and independence

Independence remains paramount when selecting third-party auditors. The EMA Quality of Medicines guidelines stipulate that no conflicts of interest should exist between the organization performing the audit and the auditee. Specifically, auditors must not have been employed by the auditee within the last three years or have any financial interest in the organization.

Quality managers should verify auditor qualifications through detailed CV reviews that confirm appropriate education, experience, and specialized training. External auditors should possess technical knowledge specific to the processes being audited—for instance, biopharmaceutical expertise for auditing biopharmaceutical APIs.

Importantly, third-party audits commissioned by API manufacturers themselves are invalid for regulatory purposes; only audits ordered by pharmaceutical companies purchasing products from these suppliers are recognized by authorities.

Benefits of external audit benchmarking

External audit benchmarking provides advantages that internal assessments cannot match. Unlike internal auditors who may develop operational blind spots, independent auditors identify risks that might otherwise remain hidden until regulatory inspections occur. This proactive identification helps prevent costly warning letters and penalties.

External benchmarking also removes the “tunnel-like vision” that limits internal evaluations, offering fresh perspectives on achievable improvements. Indeed, organizations using external benchmarking typically prioritize issues more strategically, focusing on root causes rather than symptoms.

Finally, third-party audit reports often carry greater credibility with regulatory authorities due to their objective nature. As one quality assurance executive noted, “It is the objectivity of the audit that matters. That’s why it isn’t enough to conduct internal audits”.

Future Trends in GMP Auditing and Compliance

The GMP auditing landscape is rapidly evolving as technology and regulatory expectations shift. Quality managers who stay ahead of these trends will position their organizations for compliance success in 2025 and beyond.

AI-driven audit analytics and risk scoring

Artificial intelligence is fundamentally changing how pharmaceutical companies approach GMP audits. AI systems excel at analyzing massive quantities of production and quality data, identifying patterns that would escape human detection. These technologies enable risk-based audit trail reviews focused on critical data elements instead of reviewing everything. Companies implementing AI-powered quality control systems report up to a 30% decrease in quality deviations. Furthermore, machine learning algorithms help streamline audits by predicting potential compliance risks, making evaluations faster and more accurate.

Integration of IoT for real-time compliance tracking

Internet of Things technology offers unprecedented visibility into manufacturing processes. IoT sensors continuously monitor environmental parameters such as temperature, humidity, and air quality, generating real-time compliance data. This capability has reduced vaccine spoilage by up to 15% in recent deployments. Additionally, IoT-enabled cold chain systems track pharmaceutical products throughout the supply chain, verifying storage conditions and transport history. As companies integrate these technologies with existing manufacturing infrastructure, they gain enhanced oversight without disrupting established workflows.

Global harmonization of GMP standards

The push for consistent global GMP regulations continues to gain momentum. The Pharmaceutical Inspection Co-operation Scheme (PIC/S), now comprising 52 participating authorities worldwide, aims to harmonize inspection procedures through common standards. This alignment simplifies compliance for international manufacturers while maintaining rigorous quality requirements. Simultaneously, regulatory bodies like the FDA, WHO, and EMA are strengthening and aligning their GMP requirements to address emerging risks in pharmaceutical production. This progressive standardization enables more efficient cross-border operations without compromising product safety.

Conclusion

GMP auditing will undoubtedly remain essential for pharmaceutical quality assurance through 2025 and beyond. Throughout this article, we have examined the comprehensive nature of effective audit processes, from initial planning to final reporting. Quality managers must therefore approach audits as ongoing improvement opportunities rather than mere compliance exercises.

The most successful quality professionals certainly recognize that meticulous attention to personnel training, equipment calibration, batch record management, and environmental monitoring constitutes the foundation of GMP compliance. Additionally, proper preparation through established SOPs, dedicated war rooms, and regular mock drills significantly enhances audit readiness while minimizing operational disruptions.

Third-party audit services offer valuable external perspectives that help identify blind spots internal teams might miss. This objective evaluation often proves particularly beneficial when dealing with suppliers or when specialized expertise becomes necessary.

Looking ahead, AI-driven analytics, IoT monitoring systems, and greater global standardization of GMP requirements will transform how pharmaceutical companies approach quality management. These technological advances empower quality managers to shift from reactive compliance to proactive risk management.

The stakes for GMP compliance remain higher than ever as regulatory scrutiny intensifies. Quality managers who embrace both the fundamentals of thorough documentation and the potential of emerging technologies position their organizations for success. Effective GMP auditing ultimately protects patient safety, ensures product efficacy, and safeguards company reputation – making it not just a regulatory requirement but a competitive advantage in the pharmaceutical landscape of 2025.

Blog you can go through – How to Conduct a Successful GMP Audit: A Step-by-Step Guide

FAQs

Q1. What is the primary purpose of a GMP audit? A GMP audit ensures that pharmaceutical products are manufactured and controlled according to quality standards and current industry best practices. It aims to verify compliance with Good Manufacturing Practice regulations, ultimately safeguarding patient safety and product efficacy.

Q2. How long does a typical GMP audit take? The duration of a GMP audit can vary depending on the complexity of the facility. Simple assessments may take between one to three days, while audits of complex manufacturing sites can last up to ten days.

Q3. What are some key areas that quality managers should focus on during a GMP audit in 2025? Quality managers should pay close attention to personnel training and qualification records, equipment calibration and maintenance logs, batch records and deviation handling, and environmental monitoring and cleaning validation processes.

Q4. How can companies prepare for a GMP audit? Companies can prepare by creating a GMP audit SOP, providing comprehensive staff training, setting up a dedicated audit war room, and conducting regular internal audits and mock drills. These steps help ensure readiness and minimize disruptions during actual audits.

Q5. What future trends are expected to impact GMP auditing? Emerging trends in GMP auditing include AI-driven audit analytics and risk scoring, integration of IoT for real-time compliance tracking, and global harmonization of GMP standards. These advancements are expected to enhance efficiency and effectiveness in maintaining compliance.