Why Quality Assurance Fails Without Regulatory Compliance: Expert Analysis

Quality assurance and compliance are inseparable partners in today’s manufacturing landscape. When organizations separate these critical functions, they risk facing hefty fines, production shutdowns, and significant reputational damage. In fact, non-compliance with regulations not only leads to legal penalties but can also endanger public safety.

We understand that implementing quality assurance best practices without proper regulatory compliance frameworks creates a dangerous gap in manufacturing operations. For large organizations especially, the long-term consequences of non-compliance , including costly litigation and damaged customer relationships, significantly outweigh the initial investment in effective quality assurance and regulatory compliance systems. At its core, manufacturing regulatory compliance serves as a protective shield against both penalties and reputational harm. Throughout this article, we’ll explore why compliance quality assurance fails without regulatory oversight and how the most successful organizations approach this critical relationship as a balance between three fundamental elements: people, process, and technology.

Why Regulatory Compliance is Core to QA Success

“You have to evaluate compliance not as an expense, but as a money saver. Sure, managing compliance takes resources, but it’s nowhere near as expensive as the costs associated with a breach.” Paul Koziarz, President and General Manager of Regulatory Compliance at CSI

Regulatory compliance serves as the foundation upon which successful quality assurance systems are built. In today’s highly regulated environment, organizations cannot afford to view compliance as merely a checkbox exercise it represents a strategic imperative that drives business sustainability and customer confidence.Legal accountability in regulated industries

The financial consequences of non-compliance are staggering. In 2021 alone, the U.S. Federal Trade Commission imposed on five companies that violated the Children’s Online Privacy Protection Act, while simultaneously enforcing strict multi-year compliance requirements. Even more sobering, over 440 companies in the EU faced combined penalties surpassing USD 1.00 billion for failing to comply with the General Data Protection Regulation.fines exceeding USD 2.00 million

Furthermore, the fintech sector illustrates this reality clearly. A recent survey revealed that 93% of fintech companies struggle to meet compliance requirements, with in compliance fines within a single year. These figures underscore the critical nature of integrating regulatory compliance into quality assurance processes from the outset.more than 60% paying upwards of USD 250,000

Organizations operating in pharmaceuticals, medical devices, automotive, and aerospace sectors face particularly stringent demands. For these industries, failure to meet regulatory standards can result not only in financial penalties but potentially in the revocation of manufacturing licenses or complete market exclusion.

Customer safety and trust implications

Beyond legal ramifications, compliance directly impacts customer safety and organizational reputation. Quality assurance professionals play a crucial role in ensuring products meet required safety standards, particularly in industries where consumer health is at stake.

According to research, businesses that prioritize adherence to compliance standards experience approximately 20% improvement in customer satisfaction. This correlation exists because compliance ensures products meet safety standards, perform as expected, and provide clear labeling with appropriate instructions and warnings.

Therefore, when quality assurance operates within a robust compliance framework, it builds a foundation of trust with both customers and regulatory bodies. This trust translates into tangible business benefits, as companies that actively integrate compliance initiatives can reduce operational risks by up to 30%.

How compliance frameworks shape QA processes

Regulatory standards fundamentally shape how quality assurance processes are designed and implemented. Major frameworks that guide compliant QA processes include:

· FDA 21 CFR Part 11 governing electronic records and signatures

· Good Manufacturing Practices (GMP) establishing quality control standards

· ISO 9001 and ISO 13485 defining quality management system requirements

These frameworks influence everything from documentation requirements to testing methodologies. Quality assurance professionals must develop procedures, conduct internal audits, and ensure adherence to these standards through comprehensive documentation and record-keeping.

Consequently, organizations that implement structured testing protocols aligned with regulatory requirements experience significant improvements. a study found that 82% of companies faced fewer compliance issues after implementing such protocols.

The integration of quality assurance and regulatory compliance enables a proactive approach to risk management. Rather than merely responding to errors, a robust QA system built around compliance requirements actively identifies potential issues before they impact consumers or trigger regulatory actions. This preventative mindset represents the core reason why regulatory compliance is essential to quality assurance success.

What Happens When QA Operates Without Compliance

Image Source: GMP Insiders

The separation of quality assurance from compliance frameworks creates significant vulnerabilities for organizations. Despite having functional products, companies without proper regulatory documentation face severe consequences that extend beyond simple procedural issues. These penalties affect financial stability, market presence, and ultimately, customer trust.

Case study: Medical device recall due to missing ISO 13485 documentation

A startup producing orthopedic implants faced regulatory action when auditors discovered missing batch records and incomplete supplier documentation. Although the implants themselves functioned correctly, the absence of robust documentation and supplier quality controls violated regulatory requirements, forcing a preventive recall. The financial impact was substantial, yet the loss of market credibility proved even more damaging.

This case illustrates a critical reality: incomplete records, missing supplier documentation, or inadequate supplier controls can trigger regulatory recalls even when the product works as intended. Moreover, manufacturers must report any correction or removal of a medical device if initiated to reduce a health risk or remedy a violation. The in the medical device industry can range from $600,000 to over $5 million, excluding long-term brand damage.cost of a single product recall

Audit failures from undocumented CAPA processes

Corrective and Preventive Action (CAPA) processes serve as a cornerstone of quality systems. Nevertheless, when these systems lack proper documentation, audits frequently fail. In fact, deficiencies related to CAPA and nonconformances are common reasons for FDA Form 483 observations and warning letters.

The FDA requires that the CAPA subsystem collect information, analyze data, identify quality problems, and take effective action to prevent recurrence. Companies without a central tracking system often manage CAPA processes inefficiently, leading to:

· Superficial investigations that fail to identify root causes

· Incomplete documentation hindering effectiveness assessment

· Ineffective communication as team members work in silos

· Potential regulatory action due to compliance failures

The average number of minor nonconformities discovered in an audit is 4-6. However, major nonconformances can prevent organizations from achieving initial certification or create barriers to re-certification based on annual surveillance audits.

Loss of market access due to non-compliance

Beyond immediate penalties, non-compliance often results in significant operational disruptions. Organizations may face manufacturing license revocation, delayed or denied market entry, and increased scrutiny from regulatory bodies.

In many industries, non-conformances must be reported and corrected to meet regulatory standards. Ignoring compliance with industry standards can result in fines, audits, loss of certification, and ultimately, market exclusion. For pharmaceutical or automotive sectors, non-conformances may breach safety protocols, jeopardizing both financial stability and public safety.

Furthermore, poor document control can expose companies to legal actions, settlements, and reputational damage. Non-compliance may instantly disqualify businesses from entering regulated markets or bidding on enterprise and government contracts. Indeed, the opportunity cost far outweighs any initial compliance effort.

Ultimately, the real cost of non-compliance extends far beyond financial penalties – it appears in lost time, eroded trust, delayed growth, and internal inefficiencies. As compliance complexity increases, with 85% of leaders reporting increased complexity in the last three years, organizations must integrate compliance into quality assurance from the beginning rather than treating it as an afterthought.

Key Regulatory Standards That QA Must Align With

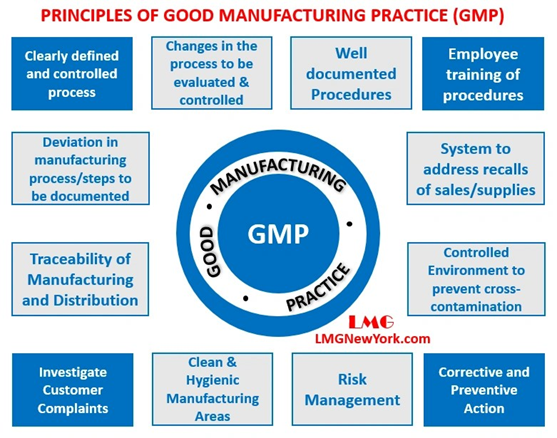

Image Source: Liberty Management Group – LMG

Effective quality assurance relies on adherence to specific regulatory frameworks that vary by industry. Understanding these standards allows QA professionals to develop robust systems that meet both customer expectations and legal requirements.

for medical devicesFDA 21 CFR Part 820

The FDA established the Quality System Regulation (QSR) under 21 CFR Part 820 to ensure medical devices consistently meet applicable requirements and specifications. Initially authorized by section 520(f) of the Federal Food, Drug, and Cosmetic Act, this regulation became effective on December 18, 1978, and underwent significant revision in 1996.

This regulation applies to all finished device manufacturers intending to commercially distribute medical devices. In January 2024, FDA issued a final rule amending the QS Regulation to align more closely with international standards by incorporating ISO 13485:2016. This revised regulation, now called Quality Management System Regulation (QMSR), will be fully implemented by 2026.

Key requirements include:

· Comprehensive design controls

· Document and record management

· Production and process controls

· Management responsibility for quality policy

· Regular quality audits

ISO 9001 and ISO 13485 in manufacturing QA

ISO standards provide globally recognized frameworks for quality management systems. ISO 13485:2016 specifically addresses medical device quality management, establishing requirements for safety and efficacy. Unlike ISO 9001, which applies broadly across industries, ISO 13485 focuses on regulatory compliance and risk management for medical devices.

The distinction between these standards is crucial for manufacturers. ISO 13485 places greater emphasis on documentation control, regulatory compliance, and risk management throughout the product lifecycle. For medical device manufacturers seeking CE marking in the European Economic Area, demonstrates quality management system compliance.ISO 13485:2016 certification

GMP and HACCP in food and pharma sectors

Good Manufacturing Practices (GMP) establish quality assurance guidelines ensuring products are consistently produced according to quality standards. Primarily applied in pharmaceutical, food, and cosmetics industries, GMP encompasses principles for facility design, sanitary operations, and production controls.

Hazard Analysis Critical Control Point (HACCP) serves as an internationally recognized risk-based system for managing food safety throughout the supply chain. Developed by the National Advisory Committee on Microbiological Criteria for Foods, HACCP addresses biological, chemical, and physical hazards from raw material production through consumption.

The seven HACCP principles include hazard analysis, critical control point identification, establishing critical limits, monitoring procedures, corrective actions, verification procedures, and record-keeping. Successful implementation requires prerequisite programs such as current Good Manufacturing Practices as an essential foundation.

Best Practices for Integrating Compliance into QA

“Quality is never an accident; it is always the result of high intention, sincere effort, intelligent direction, and skillful execution.” William A. Foster, Renowned author on quality and leadership

Integrating compliance into quality assurance requires systematic approaches that address both regulatory requirements and operational efficiency. Successful organizations recognize that merging these functions creates robust systems that prevent failures instead of merely reacting to them.Risk-based QA planning aligned with regulatory priorities

Adopting a risk-based approach to quality assurance enables organizations to allocate resources more efficiently by focusing on high-priority areas. This methodology identifies potential risks based on their likelihood and impact on quality objectives. Organizations implementing structured risk assessment see approximately 82% fewer compliance issues.

For effective implementation:

· Incorporate risk assessment methodologies like FMEA or HACCP into quality planning

· Document all risk assessment activities within QMS documentation

· Regularly reassess risks, primarily when requirements change

Automated document control and audit trails

Effective document management forms the cornerstone of compliance-driven quality assurance. Implementing digital solutions streamlines processes and maintains regulatory compliance with even the strictest standards. These systems create audit trails. time-stamped records that track user actions related to documents and transactions.

Audit trails capture critical information about document access, edits, and approvals, providing tamper-resistant evidence of compliance activities. Subsequently, these records become essential during regulatory inspections and internal reviews.

Internal audits and CAPA tracking systems

Corrective and Preventive Action (CAPA) systems are fundamental for quality management. The FDA emphasizes that CAPA must collect information, analyze data, identify quality problems, and implement effective solutions. Organizations without centralized tracking systems often struggle with inefficient CAPA processes.

Above all, ensure your CAPA program includes:

· Clear procedures for conducting failure investigations

· Root cause analysis for significant issues

· Verification of corrective actions’ effectiveness

Employee training on compliance-driven QA protocols

End-to-End Test Management: From Strategy to Success in 2025 begins with proper staff training. Effective training ensures employees understand current regulations and quality protocols. Organizations should establish KPIs to measure training impact on employee performance and organizational goals.

Data-driven compliance monitoring uses advanced tools to track and document training activities, ensuring all requirements are met and providing clear records for audits. Essentially, this approach transforms compliance from a checkbox activity into an integral part of daily operations.

Tools and Systems That Support Compliance-Driven QA

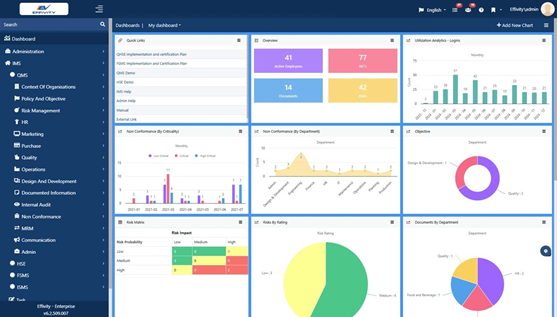

Image Source: Effivity

Modern technology empowers organizations to maintain compliance through specialized software solutions that automate critical quality assurance functions. These digital tools transform how companies manage quality processes while ensuring regulatory requirements are consistently met.

Quality Management Systems (QMS) with compliance modules

Quality Management Systems serve as formalized frameworks that document an organization’s processes, procedures, and responsibilities for achieving quality policies and objectives. Effective QMS solutions incorporate compliance modules specifically designed for regulated industries. These systems primarily help teams monitor processes, assess risks, and ensure adherence to governing bodies’ requirements.

Key features include:

· Integration with existing workflows and cloud providers

· Automated evaluations using industry-specific templates

· Customizable controls aligned with regulatory frameworks

· Real-time dashboards for compliance monitoring

Arena QMS, for instance, meets stringent standards including FDA 21 CFR Part 820 and ISO 13485, making it ideal for medical device manufacturers.

Automated compliance reporting tools

Automated reporting tools significantly reduce the time required for compliance activities. transforming what typically takes 100+ hours manually into just 10-15 hours. These solutions generate detailed analytics on compliance metrics and trends, helping teams identify areas of potential risk.

Tools like Vanta support over 35 security and privacy frameworks including SOC 2, ISO 27001, and HIPAA, enabling cross-mapping of controls across existing frameworks. Additionally, through automated evidence collection and continuous monitoring, organizations can reduce time spent on manual compliance tasks by approximately 50 hours monthly.

Version-controlled document management systems

Version control systems create detailed audit trails that log what changed, who made the change, and when it happened. crucial for both internal review and regulatory requirements. This tracking ensures teams always access the most recent, approved versions of documents, reducing risks that could cascade into larger compliance issues.

End-to-End Test Management: From Strategy to Success in 2025 requires robust version control with automated version tracking, user permissions, approval workflows, and immutable audit trails. These systems preserve original files while tracking every change, making tampering nearly impossible to hide. a critical requirement for maintaining legal defensibility and compliance.

Conclusion

Quality assurance and regulatory compliance work together as essential partners rather than separate functions. Throughout this article, we’ve examined why this partnership matters and how separation leads to costly consequences. Undoubtedly, organizations that treat compliance as merely a checkbox exercise face significant risks including hefty fines, product recalls, and market exclusion.

The evidence clearly demonstrates that compliance-driven quality assurance creates a protective framework. Companies implementing structured testing protocols aligned with regulatory requirements experience approximately 82% fewer compliance issues. Additionally, businesses prioritizing adherence to compliance standards see roughly 20% improvement in customer satisfaction. These statistics highlight the tangible benefits of integration.

Regulatory frameworks such as FDA 21 CFR Part 820, ISO standards, and Good Manufacturing Practices establish the foundation upon which effective quality systems must build. Therefore, understanding these requirements becomes crucial for developing QA processes that satisfy both customer expectations and legal obligations. Risk-based QA planning, automated document control, robust CAPA tracking systems, and comprehensive employee training serve as cornerstones for successful compliance integration.

Modern technology further strengthens this relationship. Quality Management Systems with specialized compliance modules, automated reporting tools, and version-controlled document management systems transform manual processes into streamlined operations. These solutions reduce compliance workload while simultaneously enhancing accuracy and consistency.

The path forward requires viewing compliance not as a burden but as a strategic advantage. Organizations must balance three fundamental elements. People, process, and technology, to create QA systems that meet regulatory requirements while driving business growth. Compliance-driven quality assurance ultimately protects both companies and consumers, creating products that are not just functional but also safe, consistent, and trustworthy.

Your investment in integrating these critical functions yields substantial returns through risk reduction, improved product quality, enhanced customer trust, and sustainable market access. Quality assurance without regulatory compliance simply cannot succeed in today’s complex manufacturing environment.

Key Takeaways

Quality assurance without regulatory compliance creates dangerous gaps that lead to costly failures, legal penalties, and market exclusion. Here are the essential insights every organization must understand:

• Compliance isn’t optional, it’s financially critical: Non-compliance costs exceed $1 billion in EU GDPR fines alone, while 93% of fintech companies struggle with requirements, paying over $250,000 annually in penalties.

• Documentation gaps trigger recalls even for functional products: Missing ISO 13485 records or incomplete CAPA processes can force product recalls costing $600,000-$5 million, regardless of product quality.

• Risk-based QA planning reduces compliance issues by 82%: Organizations implementing structured testing protocols aligned with regulatory frameworks like FDA 21 CFR Part 820 and ISO standards experience significantly fewer violations.

• Automated systems transform compliance from burden to advantage: Modern QMS platforms reduce manual compliance work from 100+ hours to 10-15 hours while providing real-time monitoring and audit trails.

• Integration drives measurable business results: Companies prioritizing compliance-driven QA see 20% improvement in customer satisfaction and 30% reduction in operational risks through proactive risk management.

The bottom line: Quality assurance and regulatory compliance must function as integrated partners, not separate departments. This strategic alignment protects organizations from penalties while building customer trust and ensuring sustainable market access in today’s highly regulated environment.

FAQs

Q1. How does regulatory compliance differ from quality assurance? While regulatory compliance focuses on meeting government regulations, quality assurance aims to deliver high-quality products to consumers. Regulatory affairs professionals ensure products comply with legal requirements, whereas quality assurance professionals concentrate on maintaining product quality standards.

Q2. What impact do regulatory requirements have on quality assurance practices? Regulatory requirements significantly shape quality assurance practices by setting product and service standards, dictating business processes, and fostering a culture of continuous improvement. They provide a framework for quality management systems and influence how organizations approach quality control.

Q3. What are the key components of effective quality assurance? Effective quality assurance comprises five key components: Planning (setting objectives), Processes (steps to achieve goals), People (implementing quality standards), Performance (measuring through KPIs), and Products (the final output). These elements work together to ensure comprehensive quality management.

Q4. What factors influence quality assurance in regulated industries? Several factors affect quality assurance in regulated industries, including regulatory compliance, technological advancements, economic conditions, customer trends, supply chain management, competitive landscape, and environmental considerations. Understanding these influences is crucial for implementing proactive quality improvement measures.

Q5. How can organizations integrate compliance into their quality assurance processes? Organizations can integrate compliance into quality assurance by implementing risk-based QA planning, using automated document control systems, establishing robust CAPA tracking mechanisms, and providing comprehensive employee training on compliance-driven QA protocols. Utilizing modern quality management systems with compliance modules can also streamline this integration.

Recent Post

- Artificial Intelligence Compliance Monitoring in Life Sciences: A New Standard for GxP Excellence

- Mastering Computer System Validation: A Practical Guide for Life Sciences

- What is the Importance of the Validation of the System: A Pillar of Life Sciences

- The V-Model in Computer System Validation (CSV): A Strategic Framework for Life Sciences Compliance

- GCP Audit (Good Clinical Practice Audit): Ensuring Clinical Trial Compliance and Quality